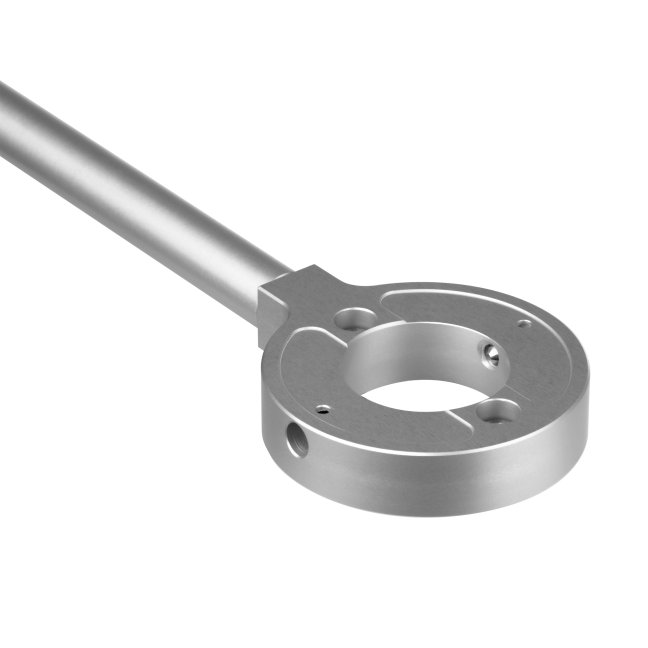

Industrial Class A pyranometer with heating and tilt sensor

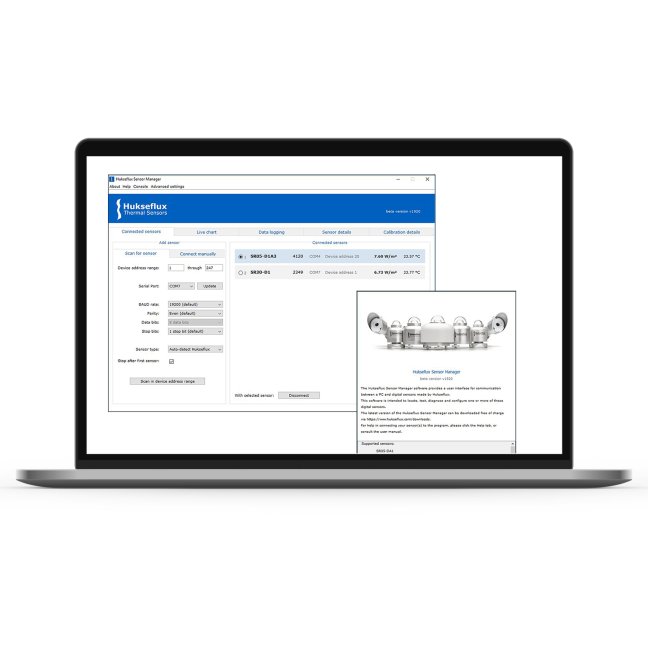

Hukseflux is proud to introduce SR300-D1. Succeeding our market-leading SR30 model, SR300-D1 is further optimised for use on PV power plants. The sensor complies with the industrial-grade requirements for sensor surge immunity and installation safety. SR300-D1 is intended for deployment where the highest measurement reliability and accuracy are required.

- designed for IEC 61724-1 Class A compliant PV system performance monitoring

- internal heating for dew and frost mitigation in all climates

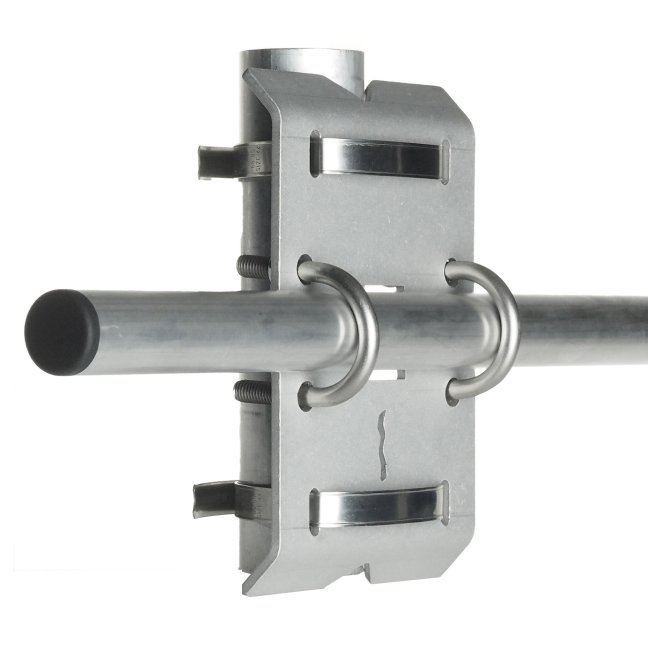

- integrated surge protection, designed to withstand the extreme conditions encountered on PV power plants, upgradable to 4 kV with optional SPD01 Surge Protection Device

- RS-485 isolation: Galvanic isolation, for reliable operation and flexibility in system design

- compliant with IEC 61326-1 “Industrial equipment” – rated for Industrial Electromagnetic Environments

- enables system designers to comply with local safety regulations

- supported by a worldwide calibration organisation for the lowest total cost of ownership

Specifications

- hemispherical solar radiation

- sensor tilt angle (3 components x, y and z)

- spectrally flat Class A pyranometer

- meets Class A PV monitoring system requirements

or contact us: info@hukseflux.com