Geotechnics / soil thermal route analysis

Hukseflux is market leader in "thermal needle" thermal conductivity sensors. The main application of these sensors is in measurement of soil thermal conductivity and resistivity.

There are two product categories: the first consists of scientific systems (needle types TP02 and TP08, with system type TPSYS02). The second category is systems designed for robustness rather than accuracy, with systems FTN02, MTN02 and TNS02.

Watch our video to see systems for soil thermal conductivity measurement at work:

Soil thermal route surveys

When designing infrastructure, the thermal properties of the soil may play a role. Thermal conductivity is a material property. It expresses how well a material conducts heat under steady state conditions.

Soil thermal conductivity matters for example when designing:

- transport of electricity through high voltage electric cable

- transport of heated oil

- geothermal heating systems

During the design phase of a project, often the soil thermal properties of the entire trajectory or the location are measured.

What is measured

The measured quantity is thermal conductivity in W/(m·K). Users may also call this the “K-Value”. Other users talk about the thermal resistivity. The latter is simply the inverse of the thermal conductivity in m·K/W.

There are standards for measurement of soil thermal conductivity. The most commonly used are:

- ASTM D5334-14 Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure

- IEEE Std 442-1981(Reaffirmed 2003), IEEE Guide for soil Thermal Resistivity Measurements

Both methods rely on thermal needles. These needles are inserted into the soil.

You may measure:

- on-site, at the exact spot requested, under local conditions

- in the laboratory, using a specimen that is collected on-site, replicating local conditions during collection as well as possible

- in the laboratory, using a specimen that is collected on-site, saturating and drying out the specimen

During collection, also other parameters are taken down:

- density

- soil type

After the measurement, in particular in the laboratory, many users will determine:

- dry density

- water content of the specimen at the moment of collection by calculation from the density after collection and the dry density

- In some cases: thermal conductivity in two extreme conditions: dry and saturated

- In some cases: soil thermal stability according to IEEE P 1254

When preparing for the high voltage power cables, the main consideration is that the temperature of the plastic insulation must remain below 80 °C. It is important to establish the most dangerous situation; i.e. the thermal conductivity of the dry soil.

Specifications

What you must know about thermal conductivity of soils:

- Soil thermal conductivity depends on soil type, density and water content

- Temperature dependence is small in the order of 0.1 %/K

- From the dry condition, adding moisture, the change of thermal conductivity is steep for the first 10 % soil water content (by mass), slower for higher percentages

- Sand has the largest variability as a function of moisture content, clay a lower variability. Loam in between. This has to do with particle thermal properties and particle shape

- Soils with mixed rock and smaller grains are hard to analyse with the thermal needle method. However, most solid rock has a higher thermal conductivity than the saturated soil, so a normal measurement will under-estimate the thermal conductivity

- Measurement times are in the order of 10 min

Table 1 Reported soil thermal conductivity, as known to the author, in different soil types in W/(m·K).

| Range of all reported values for granular soils | 0.15 to 4 |

| Saturated soil | 0.6 to 4 |

| Sand perfectly dry | 0.15 to 0.25 |

| Sand moist | 0.25 to 2 |

| Sand saturated | 2 to 4 |

| Clay dry to moist | 0.15 to 1.8 |

| Clay saturated | 0.6 to 2.5 |

| Soil with organic matter | 0.15 to 2 |

| Solid Rocks | 2 to 7 |

| Tuff (porous volcanic rock) | 0.5 to 2.5 |

What you must know about thermal needle measurement

- The measurement relies on the transient measurement of temperature versus time of a needle inserted into the soil when subject to stepwise constant power heating. In insulating soils the temperature rise is faster than in conducting soils

- The needle method is best suitable for homogeneous soils with particle sizes smaller than the needle diameter (< 6 x 10-3 m)

- The needle must have a good contact to the soil and not move

- The measurement must be low-power so that there is no local evaporation of water.

- There are special accessories such as guiding tubes that may help you when working on hard soils or in concrete or cement.

- A typical day of measurement starts with verification of the measurement accuracy; a measurement in a calibration material

- You may expect measurement accuracies in the field in the order of 10 %, in the laboratory this may be better

- You must visually analyse the data. This is required by the standards. The indication of the standard deviation of the measuring system is an indication only

Selecting a sensor or measuring system

a typical checklist is:

- what is the application? In the field, in te laboratory or mixed use

- what are the accuracy requirements; high or low

- how are you measuring (in the field at the exact spot, in the field on specimens, in the lab)

- are you working onshore or offshore

- at what depth do you measure

- are there any special experimental requirements for example a dryout experiment, sediment core sample testing, mobile use

- what are the available specimen dimensions

- what is the temperature range over which a measurement must be made

- what are the accuracy requirements

- what other things must be measured, such as density, heat capacity

What we contribute

Hukseflux has been designing soil thermal conductivity measurement sensors and systems for over 20 years. In the course of the years, we have added many sensors to our product range. We also offer measuring services and rent out equipment.

Hukseflux offers the following measuring systems:

- FTN02: a 100 % field instrument

- MTN02: for mixed field / laboratory use

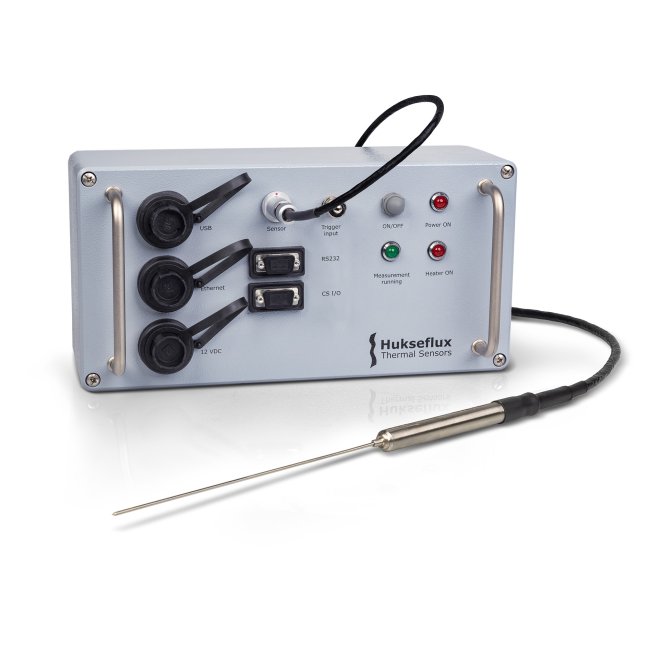

- TPSYS02: a scientific measuring system typically for the laboratory, but also useful in case you are only working with soft sediments and dryout experiments

For thermal needle types TP07 (used in MTN02) and TP08 and TP02 Hukseflux offers stainless steel “guiding tubes”. Using these tubes it is possible to measure in hard materials such as cements and thermal backfill (heavy clay) and dried-out soil by casting them into specimens.

For all models there are Calibration Reference Cylinders available, providing a traceable reference material. Hukseflux is also capable of supplying custom designed models (heavy duty, pressure resistant) for field or offshore applications.

- sell our “standard” product range of sensors and systems

- rent out systems, including support for analysing data

TP02 and TP08 are primarily intended for use in the lab providing the highest possible measurement accuracy. Although intended for indoor measurement, TP02 and TP08 may be taken outdoors for on-site testing, provided that care is taken during operation. Operation in soft soils, such as sediments is easy. In harder soil holes must be pre-drilled, or guiding tubes may be used. TP02 and the smaller TP08 may be purchased as a single needle or a as part of a complete turnkey system TPSYS02. Models TP02 or TP08 can be operated using "standard" electronics, found in most measurement laboratories. The user should carefully consider which probe to use. The standard model is TP02. This offers the highest accuracy, the lowest sensitivity to external influences and the best performance at higher or lower temperatures. In case the specimen size for TP02 (typically 150 x 10⁻³ m height) is not available, use of TP08 should be considered. TP08 is shorter than TP02, but its general operation is identical to that of TP02. A special sample container (TP08-CO) is available for use with TP08. TP08 is also often used in analyses of sediment cores in offshore experiments. Many times insertion of TP08 from the side of the core is possible.

For field experiments, Hukseflux offers measuring systems FTN02, MTN02 and the combined TNS02. These “heavy duty” systems are equipped with robust thermal needles suitable for penetrating soft as well as harder soils. The FTN02 system is designed for field use, in particular surveys for high voltage electric cables (not during operation) typically measuring at a depth of 1.5 metres below the soil surface. FTN02 includes a 1.4 metre long lance (model LN02) at the tip of which a very robust (6.3 x 10⁻³ m diameter) needle (model TP09) is mounted. Using a lance rather than digging trenches saves time. The MTN02 system is suitable for laboratory experiments as well as field experiments. The 3.5 x 10⁻³ m diameter needle (model TP07) is mounted on a small insertion tool (IT03). Models TP07 and TP09 are more robust than TP02 or TP08; however, the attainable measurement accuracy is considerably lower.

How to request a thermal conductivity measurement service

- look at our selection guide

- read our specimen requirements document

- fill in our request form

How to rent a thermal conductivity measuring system

- unfortunately we have discontinued our rental services for all systems

Advantages

Hukseflux is a leader in thermal conductivity measurement. We offer:

- assistance: help you select the best sensor or system for your application

- proven performance: in most applications we have experience

- worldwide support – specialists available in the major economies

- compliance with standards: IEEE, ASTM, ...

- good price versus performance; also rental systems

- traceability: formal metrological traceability to international standards

- training:

Take a look at our selection of suitable sensors: