5 recent heat flux applications; from smartwatches to mattresses

Heat flux applications and heat flux measurements have recently become more popular. Heat flux sensors measure heat transport through a specific area per unit of time. Unlike temperature, heat flux gives a dynamic picture of how energy moves as heat. If you are familiar with heat flux and its measurements, you might wonder when and where it is used. There are many heat flux applications and ways of measuring heat flux; this article shows five innovative, recent heat flux applications. It helps understand how measuring heat flux can enhance the performance and efficiency of various products and processes.

If you are not familiar with heat flux, make sure to read: What is heat flux?

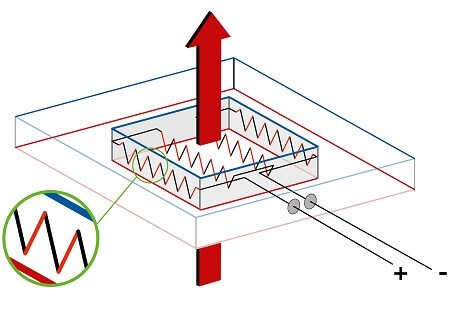

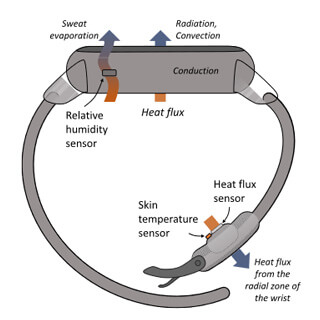

1. Measuring heat flux in smartwatches

showing the main measuring components;

a heat flux sensor, skin temperature sensor and

relative humidity sensor. Photo: IEEE

Devices like activity trackers and smartwatches have become increasingly popular for monitoring biometric signals. Data on heart rate, skin temperature, humidity, and movement allow us to live a healthier life. Most wearable electronics predict human energy consumption based on heart rate measurements. Although this “calorie” method is valid at high intensities, it is less accurate at low-intensity levels. This results in inaccurate estimations for daily net energy expenditure. Energy expenditure refers to the amount of energy a person uses at rest (low-intensity) and during physical activities (high-intensity). By accurately measuring energy expenditure, individuals can tailor their diet and exercise regimens.

the tailor-made bracelet.

A study published by IEEE augmented heart rate data with heat flux measurements. The study involved fifteen human test subjects. Its purpose was to determine whether heat flux measurements enhance the functionality of smartwatches. Figure 1 shows the custom-made bracelet. The arrows indicate heat transfer from the user to the environment. When worn, the heat flux sensor measures the conduction of bioheat from the radial zone of the user’s wrist to the bracelet. From there, the heat is transferred to the environment through convection and radiation. The bracelet is equipped with a humidity sensor to estimate the evaporative heat transfer. The skin temperature sensor was only used for control purposes, and this study did not consider the data.

The study concludes that the combination of heart rate and heat flux measurements improves the accuracy of energy expenditure estimation. The researchers also add that future wearable devices should include heat flux sensors as they provide more accurate data at low-intensity activities.

2. Monitoring heat flux in industrial ovens

Have you ever wondered how companies like Weetabix, Arnott’s, Burton’s Biscuits, etc., manufacture their products in such large quantities? Well, they do this using industrial ovens. These ovens can be in the form of conveyor belt-like ovens, as shown in Figure 3. Dough enters at one end, and the finished product exits at the other.

In these industrial ovens, the finished product sometimes fails to meet the high-quality standards required and thus cannot be sold. This may be the result of a malfunction inside the oven. However, the inside of such ovens is hard to monitor. Thistle Thermal Profiling offers a Voyager product that goes through the oven with the dough pieces to measure and record the thermal conditions, such as temperature and heat flux. This process is called oven profiling. With the use of oven profiling, you can detect unusual exposure to heat. The primary objective of this technology is to provide a clear and accurate understanding of the thermal processes and conditions inside the oven. You can quickly detect failed heating elements or burners by measuring the combination of heat flux and temperature during the journey in the oven. This helps speed up failure diagnostics and reduce downtime and any associated costs.

On the right, the heat flux sensors have black and silver

stickers for measuring total heat flux and convection,

respectively. On the left, the FHF05:15x30.

Photo: Thistle Thermal Profiling Ltd.

Figure 4 shows Thistle’s Thermal Profiling Voyager. On the right, you can see that black and silver stickers cover the heat flux sensors. The black stickers give a value on the total heat flux, while the silver provides a value on convection.

Applications and benefits:

- Fast diagnosis of oven faults: Analysing the heat flux data makes it possible to identify and rectify issues inside the oven quickly. Resulting in downtime reduction and enhancing overall efficiency.

- Product quality improvement: Thermal profiling helps ensure that the product receives even heat exposure. This results in maintaining consistent quality.

- Customisable: The Voyager system can be customised to specific requirements. This makes it suitable for a wide range of baking needs and oven designs.

Thistle Thermal Profiling uses Hukseflux’s FHF05 foil heat flux sensors to gather valuable information from industrial ovens, helping food manufacturers attain more efficient food production. This results in significantly fewer failures in the baking process and, thus, unnecessary costs.

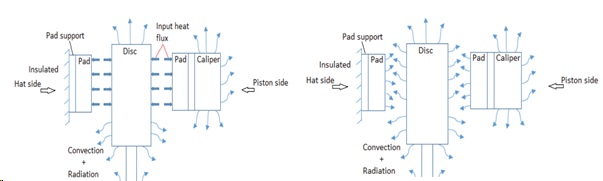

3. Heat flux measurements in automotive brake systems

Heat in brake discs is transferred by convection. Applying a heat flux sensor on the brake disc and pads can show us how heat changes during braking. Preferably, automobile manufacturers want a brake disc that does not heat up quickly and loses heat quickly. A brake disc, constantly heated by vast amounts, has a bigger chance of failure. The main objective is to optimise heat dissipation from the brake discs and pads by measuring heat transfer. Figure 5 illustrates heat flux generation and dissipation in brake discs and pads.

The thesis by Naga Kora and Srivatsan Vedanta at the Blekinge Institute of Technology in Sweden introduces an analysis of heat transfer in brake discs. The braking system is one of the most important automobile components for road safety. High temperatures generated during braking can lead to brake fade or failure. In their thesis, they investigate and describe what causes higher heat fluxes and how such fluxes can be avoided.

Their study demonstrates that their analysis can accurately predict the thermal behaviour of brake discs during various braking scenarios. The analysis uses Finite Element Analysis (FEA), a computational technique that models and predicts how objects react to real-world factors. This includes vibration, humidity, temperature, and other physical effects. The analysis results are then compared to the experimental data from heat flux sensors. In the study, the analysis results are similar to the experimental results, meaning their simulation changes according to real-world conditions.

Through this simulation, you can analyse the reliability of the brake discs under extreme stress. From this simulation, engineers can design brake systems that are better at managing high temperatures -resulting in fewer brake failures and more safety on the road. Such analysis can also be used in motorsports. In Formula 1, for example, brake systems must endure extremely high temperatures. Measuring heat flux on different brake disc designs can produce higher-quality brake systems. This will result in fewer DNFs and faster lap times.

4. Heat transfer in mattresses: ensuring comfort and safety

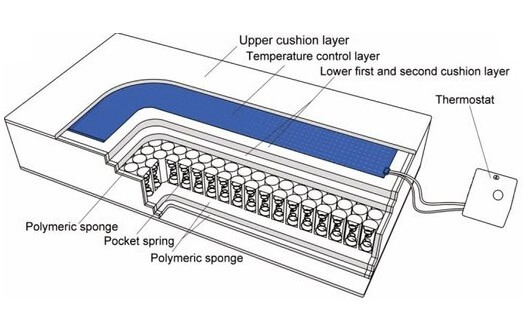

Illustration: Nanjing Forestry University in China.

Sleep is one of the most critical factors for a healthy lifestyle. Manufacturers continuously try to improve their mattresses to offer their customers a restful night. People often sleep worse in warmer climates. This is because the human body needs to drop its body temperature to fall asleep.

A study from Nanjing Forestry University in China aims to evaluate the heat transfer performance of thermoelectric-driven conditioned mattresses. The researchers intend to reduce the interface temperature between the human body and the mattress. This should satisfy the personal sleep thermal comfort requirements in hot conditions.

The mattresses in question utilise an integrated system of water cushions or circulating water pipes. They can regulate the surface temperature through a thermoelectric cooling system. But which mattress has the best cooling effect: the one with water cushions or the one with circulating water pipes? The researchers measured the heat transfer between different cushion layers and checked how efficiently they could cool the upper layer. Heat flux sensors allowed them to analyse which mattress cooled the best without losing cooling performance through the layers. The mattress with integrated water cushion seemed to have a superior cooling performance compared to the circulating water pipe mattress. This study provides a new idea of applying a temperature control layer to mattresses to improve comfort during sleep.

5. Heat control in greenhouses through heat batteries

In 2020, a start-up in the Netherlands named Thermeleon came up with the idea of a “heat battery” for greenhouses. This product promises to decrease the gas consumption of greenhouses by 10 to 30 % without using pumps, electricity, or gas. The system itself does not require energy. It stores excess heat during the day and releases it at night. Because of this system, windows can stay closed longer, less CO2 is released, and less electricity is needed. With a heat battery, you can also increase crop yields because the crops will be in optimal conditions more often.

Thermeleon first tested their product in September 2023 at Koppert Cress in Monster, the Netherlands. Here, Thermeleon placed the heat battery in a greenhouse of one hectare. Next to it, a reference greenhouse without a heat battery is situated. The first results were positive in cooling, heating, and horizontal temperature uniformity. The term horizontal temperature equality refers to the uniformity of temperature over a large area at the same height. This is crucial so that all the crops experience the same temperature conditions.

During the production of the heat battery, Hukseflux’s heat flux sensors with black and gold stickers were used to measure the amount of heat transferred into the greenhouse. Using the heat flux sensors, Thermeleon can change the parameters of the heat battery to achieve optimal conditions for the greenhouses. As you can see, innovative heat flux applications can also contribute towards a sustainable future.

Watch the video below in which Liesanne Wieleman, founder of Thermeleon, explains more about using Hukseflux heat flux sensors during their research of the heat battery.

Order your heat flux sensors

From this article, you can see that there are many ways in which measuring heat flux can benefit the development of products. Contact us today if you want to use heat flux sensors in your research. Our engineers can help you decide which heat flux sensor you need for your application.