Heat flux sensors: the latest technologies

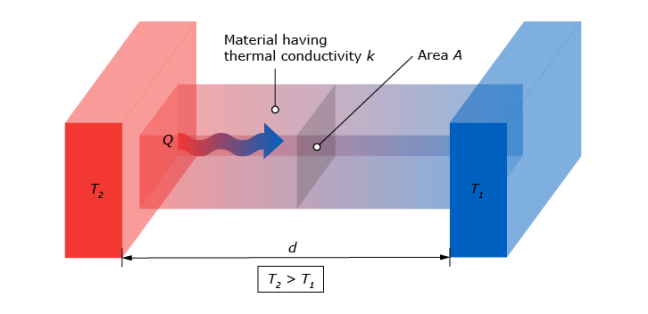

A heat flux sensor is a sensor that detects or measures heat flux, an energy flux through a surface given in W/m². The sensor converts the heat flux to an electrical signal that can be easily measured and displayed. Hukseflux is the market leader in advanced heat flux sensors that stand out for their accuracy, reliability, and design. This article shows you the latest product details and compares the specifications of our wide range of heat flux sensors. We provide criteria to help you select the sensor you need for your specific application.

What is a heat flux sensor?

A heat flux sensor measures the rate at which heat energy is transferred through a surface. Heat flux sensors have increasingly become essential tools in environmental research, monitoring of industrial processes, and much more. Using these thermal sensors allows for the optimisation of energy efficiency and improvement of thermal management. Whether it’s for ensuring better insulation and thermal conditions in buildings or enhancing the performance of solar panels. In today's world, heat flux sensors are indispensable in the thermal and energy landscape. Hukseflux provides the latest technology in heat flux sensors, which we will now review.

New heat flux sensors at Hukseflux

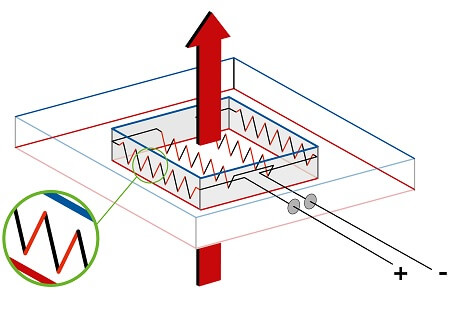

alternating pattern of two different conductors.

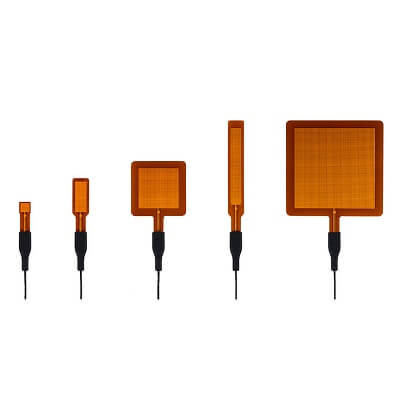

1. Foil Heat Flux (FHF)

To understand our FHF series and our other heat flux sensors, a thermopile's concept and working principle must be explained first.

The fundamental component of Hukseflux heat flux sensors is a thermopile, which is manufactured using an alternating pattern of two dissimilar conductors and a thin layer of material. Across this thin layer, temperature differences are measured, resulting in a voltage output signal and heat flux measurement.

What makes our FHF series unique is how the foil part is manufactured and what it can do. This heat flux sensor series can be bent to a certain radius without losing thermal resistance and without sensitivity changes.

Inside Hukseflux’ foil heat flux sensors, multiple small thermal spreaders cover the sensor forming a conductive layer. This helps reduce dependence on the measurements' thermal conductivity, making the sensor's sensitivity independent of its environment. Compared to other foil heat flux sensors that can be bent, our FHF series does not change its properties, making our measurements more accurate. Many competing sensors do not have thermal spreaders, making Hukseflux’ sensors stand out.

Our newest heat flux sensor, FHF06, comes in one dimension, 25x50 x 10⁻³ m. It is sensitive, flexible, thin, and can withstand exceptionally high temperatures. Our previous FHF05 series is also thin, sensitive and flexible but does not work at the high-temperature ranges of the FHF06. This series comes in various dimensions, (10 x 10, 15 x 30, 50 x 50, 15 x 85, 85 x 85) x 10⁻³ m. These different dimensions make it possible to measure heat flux in various applications. For example, measuring heat flux from electronics, such as chips, is possible with the FHF05-10x10. On the other hand, the FHF05-15x80 is more useful when measuring heat flux from a tube with a certain radius. There are also two self-calibrating sensors with heaters in the FHF05 series in dimensions 50x50 and 85x85. The heater allows you to perform self-tests, verifying sensor functionality and stability during use without removing the sensor.

| Specifications | FHF06 | FHF05 |

| Measurement range (W/m²) | (-20 to +20) x 10³ | (-10 to +10) x 10³ |

| Rated bending radius (m) | ≥ 7.5 x 10⁻³ | ≥ 7.5 x 10⁻³ |

| Sensor thermal resistance (K/(W/m²)) | 12 x 10⁻⁴ | 11 x 10⁻⁴ |

| Sensor thickness (m) | 0.38 x 10⁻³ | 0.4 x 10⁻³ |

| Sensitivity (nominal) (V/(W/m²)) | 25x50: 5 x 10⁻⁶ | 10x10: 1 x 10⁻⁶ 15x30: 3 x 10⁻⁶ 15X85: 7 x 10⁻⁶ 85x85: 50 x 10⁻⁶ |

| Rated temperature range- continuous use (°C) | -70 to +250 | -70 to +120 |

2. Schmidt-Boelter Gauge (SBG) & Gardon Gauge (GG)

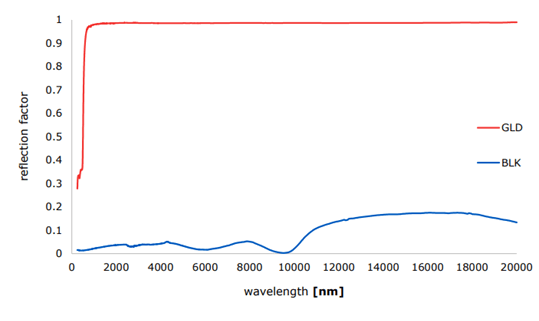

The Schmidt-Boelter Gauge (SBG) & Gardon Gauge (GG) are very similar but differ in specifications and how they are built. Most important is that they both measure heat flux. The difference lies primarily in the design. Usually, a Gardon Gauge has a thin metal foil attached to a substrate with a circular water-cooled body. A Schmidt-Boelter Gauge typically has a water-cooled sensor with a blackened thermopile.

At Hukseflux, our SBG series uses both Gardon Gauge and Schmidt-Boelter sensor technology. This combination of foil technology (in GG) and thermopile technology (in SBG) provides a unique sensor in the thermal sensor industry. Both our SBG and GG series are designed for measurements in an environment in which heat flux is dominated by radiation. Therefore, these sensors are mainly used for fire and fire resistance test reactions. Using other heat flux sensors in these high heat flux levels may damage or malfunction your sensor. In the table below, some specifications of the SBG series and GG are given. This table shows that the GG01 can withstand even higher heat fluxes than the SBG series. This also comes with a relatively slower response time.

|

|

|

| Specifications | SBG04 | SBG01 | GG01 |

| Measurement range (W/m²) | 100 x 10³ | (5, 10, 20, 50, 100, 200) x 10³ | (250, 500, 1000) x 10³ |

| Sensor technology | both Gardon and Schmidt-Boelter | both Gardon and Schmidt-Boelter | Gardon |

| Rated cooling water flow | > 10 l/h (0.003 l/s), preferably 30 l/h (0.01 l/s) | > 10 l/h (0.003 l/s) preferably 30 l/h (0.01 l/s) | > 50 l/h (0.014 l/s) |

| Response time (63%) | - 100 x 10³ W/m²: < 250 x 10⁻³ s | - 5, 10 x 10³ W/m²: < 450 x 10⁻³ s - 20, 50 x 10³ W/m²: < 250 x 10⁻³ s - 100, 200 x 10³ W/m²: < 200 x 10⁻³ s | - 250 x 10³ W/m²: < 250 x 10⁻³ s - 500 x 10³ W/m²: < 200 x 10⁻³ s - 1000 x 10³ W/m² < 100 x 10⁻³ s |

3. Heat Flux Plate (HFP)

Heat flux plates at Hukseflux are the world’s most popular sensors for heat flux measurements. They are used for heat flux measurements in the soil, through walls, windows, building envelopes, and much more.

Hukseflux manufactured the HFP series with a ceramics-plastic composite body for a small total thermal resistance. This sensitive heat flux sensor results in accurate measurements of small heat fluxes. The table below shows that the HFP03 is even more sensitive than the HFP01. This sensitivity can also be created by putting several HFP01 sensors electrically in series. A device with high sensitivity can detect smaller changes in the input quantity and produce a larger output change for a given input change. This is beneficial in applications for detecting small changes or low levels of a signal, such as soil measurements.

|

|

| Specifications | HFP01 | HFP03 |

| Measurement range (W/m²) | -2000 to +2000 | -2000 to +2000 |

| Sensitivity (nominal) (V/(W/m²)) | 60 x 10⁻⁶ | 500 x 10⁻⁶ |

| Sensing area (m²) | 8 x 10⁻⁴ | 64 x 10⁻⁴ |

| Sensor thermal resistance (K/(W/m²)) | 71 x 10⁻⁴ | 71 x 10⁻⁴ |

| Sensor thickness (m) | 5.4 x 10⁻³ | 5.4 x 10⁻³ |

| Rated operating temperature range (°C) | -30 to +70 | -30 to +70 |

| Uncertainty of calibration | ± 3 % (k = 2) | ± 6 % (k= 2) |

4. Industrial Heat Flux (IHF)

The industrial heat flux sensor is typically meant to operate in high-temperature industrial temperatures. These sensors are designed to endure extreme environments, high pressures, and water exposure, offering more resilience than standard heat flux sensors.

The sensor inside is protected by a fully stainless-steel body, making the IHF series extra robust. IHF sensors consist of both a thermopile and a type K thermocouple. The thermopile measures the local heat flux, and the type K thermocouple measures the absolute temperature of the surface on which the IHF is mounted.

HFS01 is also an industrial heat flux sensor and belongs to this category. Unlike the other IHF sensors, HFS01 is water-cooled and equipped with a black absorber. The suggested use for this sensor is mainly for flame research, fluidised beds, and solar concentrators.

The table below shows the measurement range and sensitivity of the IHF series. It shows that the IHF01 has a ten times wider range than the IHF02. Because of this, the IHF02 also comes with 25 times higher sensitivity.

|

|

|

|

| Specifications | IHF01 | IHF02 | HF05 | HFS01 |

| Measurement range (W/m²) | (-1000 to +1000) x 10³ | (-100 to 100) x 10³ | -6000 to 6000 | 0 to 800 x 10³ |

| Sensitivity (nominal) (V/(W/m²)) | 9 x 10⁻⁹ | 250 x 10⁻⁹ | 15 x 10⁻⁶ | 9 x 10⁻⁹ |

5. Flare and fire radiation sensors

Our flare radiation heat flux sensors are applicable for monitoring radiation emitted by flares and fires. These heat flux sensors are not meant for measurements but primarily for decision-supporting roles. The main purpose of these sensors is to be used in alarm systems. In high thermal radiation exposure, the radiation sensors alarm you when necessary. A safe environment for personnel typically does not exceed 5 x 103 W/m2. An alarm is activated if this heat flux level is exceeded or the sensor body exceeds 70 °C.

Typical flare and fire radiation sensors are the Hukseflux HF02 and HF03. The HF02 is suggested to be used in an outdoor environment. The HF03 is a verification instrument for monitoring the performance of permanently installed flare radiation sensors such as the HF02.

|

|

| Specifications | HF02 | HF03 |

| Measurand | Temperature and heat flux | Heat flux |

| Measurement range (W/m²) | -30 to + 100 °C, 0 to 15 x 10³ | 0 to 10 x 10³ |

| Rated operating temperature range (°C) | -20 to +70 | -10 to +40 |

| Sensitivity (V/(W/m2)) | 0.3 x 10-6 | 0.25 to 0.65 x 10-6 |

Conclusion and overview

Heat flux sensors are critical in measuring the rate heat energy transfers through a surface. These sensors are applicable in various sectors. Here is a clear overview of some of our heat flux sensors with selection criteria based on requirements, environment, and application. In the table below, we compare sensor types and not within a certain series of sensor types. For example, the sensitivity might be moderate, but within the sensor type, it could vary.

| Heat flux sensor type | Suited environment | Ideal application | Unique features | Sensitivity | Temperature range |

| FHF | diverse | varied surface types (bent, small, big surfaces) | - multiple thermal spreaders - high flexibility | high | high (especially FHF06) |

| SBG | dominated by radiation | - test reaction to fire - fire resistance testing | - both Gardon gauge and Schmidt-Baulter gauge technology - scratch-resistant absorber coating | moderate to high | moderate to high |

| GG | dominated by radiation | - test reaction to fire - fire resistance testing | - fast response time - withstands very high heat fluxes | moderate | high |

| HFP | soil, walls, building envelopes | - highly sensitive - low thermal resistance | very high | moderate | |

| IHF | high-temperature industrial environments | industrial processes | - stainless steel body - withstands high pressure, high temperature and water exposure | variable | extremely high |

| HF | dominated by radiation outdoors | alarm system | - robust - able to withstand outdoor conditions | moderate | moderate |

If you want more specifications or purchase, please check out our wide range of heat flux sensors. Or contact us to discuss your specific needs; we will help you by providing the best sensor for your application.