Heat flux sensors and their applications

Heat flux sensors are versatile sensors used in many applications. In this article, we give you an overview of some of the most important ones, from meteorological surface flux measurements to industrial monitoring. We start with a short explanation of what heat flux is and how heat flux sensors are used to conduct measurements. Next, we give an overview of the four most important general applications. We conclude by showing you which Hukseflux heat flux sensors are best suitable for these applications.

What is heat flux?

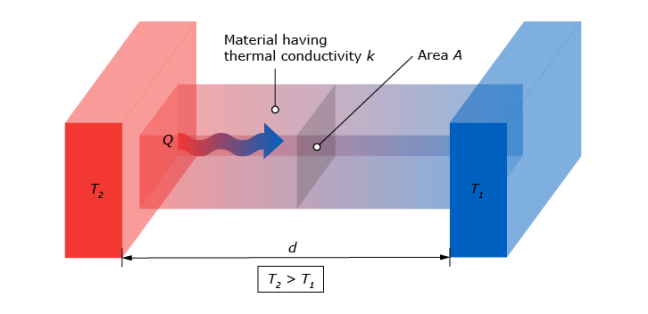

Heat flux is the amount of energy transferred from one place to the other in the form of heat. The concept is expressed in W/m². Heat always flows from a place with high temperature to a place with low temperature. Heat flux sensors can measure this flow.

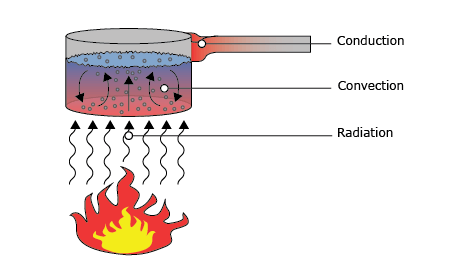

Heat flux can be divided into three different types: conduction, convection, and radiation, see Figure 1.

Conduction is the heat transfer through a solid material like a wall or a pipe. In Figure 1, this is the heat flux through the pan.

Convection happens when heat is transferred through a gas or liquid, like heat from a heater spreading throughout a room. Convection in a liquid can be seen in Figure 1.

Finally, there is radiation, which is vital in our daily life. The radiation from the sun not only gives us light, but also heat, which makes the earth liveable. For example, the radiation from the fire to heat the water, in Figure 1.

If you want to know more about this topic, read the article: What is heat flux?

The applications of heat flux sensors

Heat flux is present in many things in our lives. It influences our weather, heats up buildings and the radiation of a fire can even destroy things. Below we list four important applications where heat flux sensors are used. First, we start with surface energy flux measurements.

1. Surface flux measurement

Surface flux measurements are important for meteorological purposes. In addition to measuring solar radiation, the heat that the ground transfers is also important in this balance. The soil heat flux can be measured with a heat flux plate, like the HFP01 heat flux sensor.

The HFP01 heat flux sensor for soil measurements

The HFP01 heat flux sensor is the most popular sensor for measurements of soil heat flux. The sensor measures the conductive heat flux through the ceramic-plastic composite sensor body, see Figure 2. It does this by using a thermopile that measures the temperature difference through the body. The thermopile can convert this temperature difference into a voltage that can easily be read out by a simple data logging system.

Using this heat flux sensor has multiple advantages. It is robust and stable, because moisture does not penetrate the sensor, making the HFP01 suitable for long-term measurements in soil. Because of the passive guard, there are no errors due to the heat flux at the edge.

The sensor also has low thermal and electrical resistance, and high sensitivity, which results in less electrical noise and a more accurate measurement. Even though it has a large guard area, it is recommended to use two or more sensors for good spatial averaging. The result will be more representative of the heat flux throughout the entire area.

heat flux plate.

For an even more accurate measurement, use the self-calibrating version: the HFP01SC. It can function as a self-test when the sensor is buried in soil without the possibility of visual inspecting it or taking it to a laboratory for calibration. This sensor is a good choice when high accuracy is needed.

Another more accurate version of the HFP01 is the HFP03 ultra-sensitive heat flux sensor, which you can see in Figure 3. This sensor is used in applications with extremely low heat flux, like geothermal heat flux. The same sensitivity can be achieved by connecting several HFP01’s in series.

The HFP01(SC) and HFP03 are also used in heat flux measuring systems for buildings, but more on that in the next paragraph.

2. Building physics and insulation

A building needs good insulation to decrease the energy usage and make it more eco-friendly. But how do you find out if your building’s isolation is effective? By using a thermal resistance measuring system like the TRSYS20!

measuring system.

The TRSYS20 thermal resistance measuring system

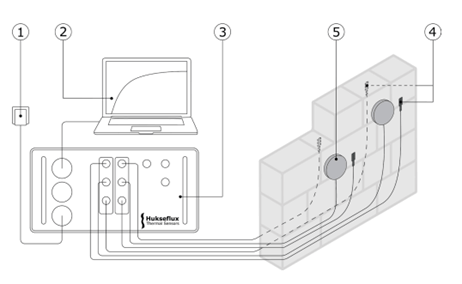

The TRSYS20 thermal resistance measuring system conducts highly accurate in-situ measurements of the R-value, Λ-value, and U-value. These values are respectively: the thermal resistance, thermal conductance, and the thermal transmittance. They are all important values in building physics to characterize the thermal environment.

two pairs of thermocouples (4) and

two HFP01 heat flux plates (5).

The system uses two HFP01 heat flux sensors combined with two pairs of thermocouples for differential temperature measurements and high-resolution electronics. They are all visible in Figure 4. Every sensor is included twice, to measure at two locations simultaneously for a better result. Figure 5 makes it clear how the measuring system has to be installed.

The high sensitivity results in measurements of low heat flux and low temperature differences. The TRSYS20 keeps measuring low values where other systems fail. It is robust, stable and survives repeated installation in multiple locations. It is also water- and corrosion proof, with an IP67 rating.

Data collection is easily controlled via a PC, without additional software. The data is collected in the measurement and control unit (MCU), which can be connected to a PC via USB. The graphical user interface for data analysis is in the form of a webpage.

3. Fire and flammability testing

In high-risk environments, where fire is likely, it is important to ensure the safety of the surrounding people. Products and buildings can be made safer by testing flammability and the risk of fire. High heat flux sensors, like the SBG04, can conduct these tests.

cone calorimeter testing.

The SBG04 heat flux sensor

One of our newest products, the SBG04 water-cooled heat flux sensor that can be seen in Figure 6, is mainly used as a calibration reference standard for testing with cone calorimeters. The dimensions and specifications are standardized for this purpose. Other applications of the sensor include flammability, fire resistance and smoke chamber testing.

Like all our sensors, the measured heat flux is converted into a voltage difference by a black-coated sensor. The black sensor surface is slightly retracted to reduce scratching. The two supply tubes for the cooling water are attached to the sensor body at a 90 ° angle for easy measuring in cone calorimeter testing.

The sensor is used in environments where heat flux is dominated by radiation with high heat flux measurements of up to 150 x 10³ W\m². Because it is an open sensor, it can also measure convective heat flux. The contribution of convection is mostly ignored, so keep this in mind when considering the measurement uncertainty.

The cable is durable, equipped with strain relief and can withstand temperatures of up to 200 °.

4. Scientific research

Measuring heat flux in engineering studies or scientific research may be of interest for many reasons. It can be interesting to know how the heat transports itself through a material, which type of heat flux is present or what the material properties are.

Next, we describe an interesting research study in which one of our sensors was used: the SBG01 heat flux sensor used in forest fire research. In a study published in 2011 (Seto & Clements, 2011), they observed how fire whirls form, also called fire tornados. The SBG01 high heat flux sensor measured the total heat flux emitted from the fire front. Together with multiple other sensors, it gave a good overview of the formation of fire whirls.

heat flux sensor.

The SBG01 heat flux sensor

The SBG01 heat flux sensor is a water-cooled sensor that can withstand high heat flux, see Figure 7. It is the sensor of choice for fire testing, but can also be used as a calibration reference standard for test equipment. The SBG01 is best used in environments dominated by radiation. It is an open sensor, so convective heat flux is also measured. The contribution of convection is generally ignored.

The SBG01 is equipped with Gardon Gauge and Smidt-Boelter Gauge technology, like the SBG04 heat flux sensor. It has a black-coated thermal sensor. This thermal sensor absorbs the incoming radiation and converts it into conductive heat. In the sensor body is a thermopile present, which measures the temperature difference between the thermal sensor and the sensor body.

The thermopile converts the temperature difference into a voltage difference. That voltage difference can easily be measured with an accurate voltmeter that can measure millivolts. Dividing the measured voltage difference by the sensitivity, results in the heat flux. The sensitivity is different for each sensor and provided with the product. The sensor can also be equipped with a thermocouple to measure the temperature.

The SBG01 is a passive sensor, and therefore it requires no power. The heat flux sensor is available in six measurement ranges, so choose the one that is closest to your application for the best results. Note however, that only measurements above 5 x 10³ W/m² are possible. Evaluate the uncertainty carefully if lower heat flux needs to be measured and/or when a significant portion is convective heat flux. Moreover, the cable of the SBG01 can withstand temperatures of up to 200 °C.

Conclusion

Heat flux sensors are really versatile, with many possible applications. In this article we elaborated on four important ones: surface energy flux measurements, building physics and insulation, fire and flammability testing, and scientific research. At Hukseflux, we offer an accurate heat flux sensor for each application. Do not hesitate to contact us if you need help choosing the right sensor.