Heat flux measurement device: sensors & measurements

If you want to conduct heat flux measurements, you should not look for a single heat flux measurement device; these measurements are performed by a measuring system.

Heat flux measurement systems often consist of multiple heat flux sensors and a measurement + data logger unit, which measures and collects data and calculates values of interest for your application.

A heat flux transducer is informally often called “sensor”. Formally, you may say that a heat flux transducer contains a thermopile sensor, which is sensitive to temperature differences.

In this article, we will first answer the question: what is heat flux? Then, we will explain how heat flux measuring systems function and give some examples of how they are applied in heat flux measurements.

What is heat flux?

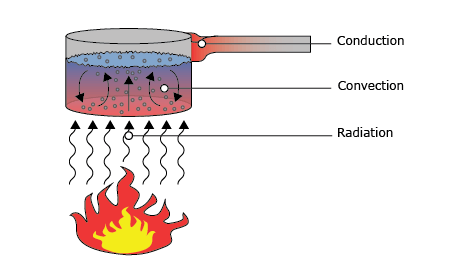

of heat flux; convection, conduction and radiation.

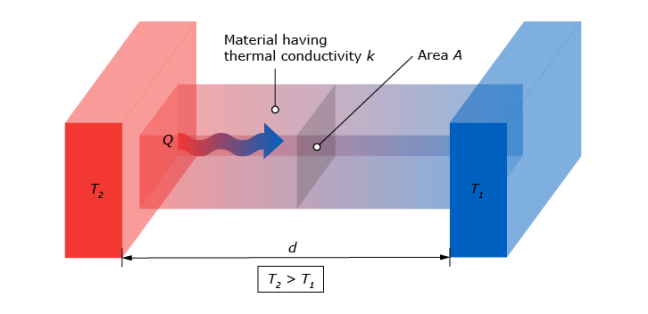

Heat flux is the amount of thermal energy (or heat) that flows through a surface over a period of time. This effect does not occur at random, heat always flows from an area with a high temperature to one with a low temperature.

Heat flux can be divided into three categories; convective, conductive and radiative heat flux. This section introduces these three forms of heat flux.

Convective heat flux is energy transferred through a fluid medium (a gas or a liquid), conductive heat flux is heat transferred through a solid medium and radiative heat flux is heat transferred through radiation. This last type of heat transfer does not need a medium.

An explanation of these different types of heat flux can be given by examining boiling water, as shown in Figure 1. The fire that heats the pan in this picture uses radiation to transfer the heat. The amount of transferred heat depends on the intensity of the source (fire in this case) and the material of the receiver (the pan).

Convection is how heat spreads through the water. The water molecules at the bottom are heated by the pan and then rise, allowing the heat to flow to other (colder) molecules.

In practice, a fire will not only use radiation, but a combination of radiation (hot glowing fire to the cold bottom of the pan) and convection (air heated by the fire rising up to the pan).

Lastly, we have conduction. This is how the heat travels through the metal of the pan itself, from the bottom to the top and even to the handle.

Both conduction and convection need a medium to be transmitted. Conduction through a solid medium, convection by a flowing gas or fluid. Radiation does not need such medium; it can be transmitted through a vacuum or a gas as long as this gas does not act as an absorber.

For a more thorough explanation of heat flux, read our article: What is heat flux?

What is a heat flux measurement device?

As said before, heat flux measurements are not conducted by one single device, but by a measuring system. Such a measuring system contains at least one measuring instrument, often a processing unit, and a display device, or data logger.

We can find exact definitions for the parts that make up the measuring system in the International Vocabulary of Metrology (VIM), which is a document for definitions used in metrology (the science of measurements).

For a measuring instrument, we find the following definition:

“Measuring instrument; device used for making measurements, alone or in conjunction with one or more supplementary devices”

From this definition, we understand that the technically correct term for a heat flux measurement device is actually a heat flux measuring instrument.

For heat flux, these measuring instruments are called heat flux transducers, often informally called heat flux sensors. A heat flux transducer generates a voltage with a known relation to the measured heat flux, but a voltage alone does not give us much information. Therefore, we need a device that can transform the generated voltage into readable data, and an output to store and/or display this data. All these devices together are called a measuring system.

How to measure heat flux?

Understanding the function of each component of the measuring system can help you when choosing which products will suit you best. The following table shows all the steps in the heat flux measuring chain with their corresponding name and function.

| Measuring chain (step) | Formal name | Informal name | Function |

| 1 | measuring transducer (with thermopile sensor) | Heat flux sensor | Converting heat flux to voltage |

| 2 | Voltmeter i.e. a transducer measuring voltages | Data logger | Measuring voltage |

| 3 | Digital signal converter | Converting voltage to heat flux via measurement equation | |

| 4 | Clock | Keeping time | |

| 5 | Digital storage; computer memory | Storing measured data as a function of time |

The combination of steps 1 and 2 is called a measuring instrument, and steps 1 to 5 make up the measuring system. At Hukseflux, we specialise in measuring instruments and can help you find which one best suits your application.

Creating your heat flux measurement system

To conduct heat flux measurements, you must find the right heat flux sensor for your application. A detailed description of this can be found in our article: Which heat flux sensor to choose? Now, follow the most important steps in choosing your heat flux sensor.

First, consider in what kind of environment the heat flux measurements will be conducted. The main categories to consider are: General, Fire & flame, High heat flux and Industrial.

With general use, we mean use in general research in low-temperature and low-heat flux (“safe”) environments, such as heat flux through walls or measurements conducted on home appliances.

The Fire & flame category is primarily about safety. These heat flux sensors are made to monitor potentially dangerous environments with high heat flux levels such as fire, flames, and concentrated solar radiation, and must follow strict guidelines.

Some sensors are made to withstand high heat fluxes, which occur in some forms of solar power generation and scientific research.

Lastly, we have industrial applications. These could be heat flux measurements in material processing, the energy sector and many others.

After finding the correct heat flux sensor, the next step is to convert the digital data. One way to do this is to use a data logger. A data logger is a device that measures and records data provided by one or multiple sensors; some can even give a real-time visualisation of the heat flux measurements.

Now that you know what heat flux is and what elements make up a heat flux measurement system, it is time to look at some examples of these systems.

First, we will look at how the Hioki LR8450-01 data logger can be integrated into a heat flux measuring system.

Conducting heat flux measurements using a data logger

connected to two flexible FHF05 heat flux sensors.

A data logger is a device that measures and stores data. The Hioki LR8450-01 data logger, for example, can be connected to one or more heat flux sensors. It stores and visualises the measurements conducted by these sensors, as shown in Figure 2.

The first step in the measurement conducting process is connecting the sensors to the data logger. The Hioki LR8450-01 data logger can be combined with plug-in modules to allow for a total of 165 Hukseflux heat flux sensors to be connected simultaneously. Colour coding on both the data logger and the ends of the signal cable of the heat flux sensor makes the connection process user-friendly.

The next step is to specify your measurements; here, important parameters like maximum heat flux and heat flux range are set.

Now, you can start the measurement. After performing the measurement, all that is left is to find a more permanent and safe storage solution for the data, either via a USB connection or an SD card. Then, you can start reviewing and post-processing the data.

Hukseflux heat flux measurement systems

Data loggers are flexible devices, but require some knowledge to be used correctly. In specific cases, readymade systems are preferable. Hukseflux makes two such systems, one for thermal resistance measurements and the other for quantifying causes and effects leading to human thermal comfort.

TRSYS20 Thermal resistance measuring system

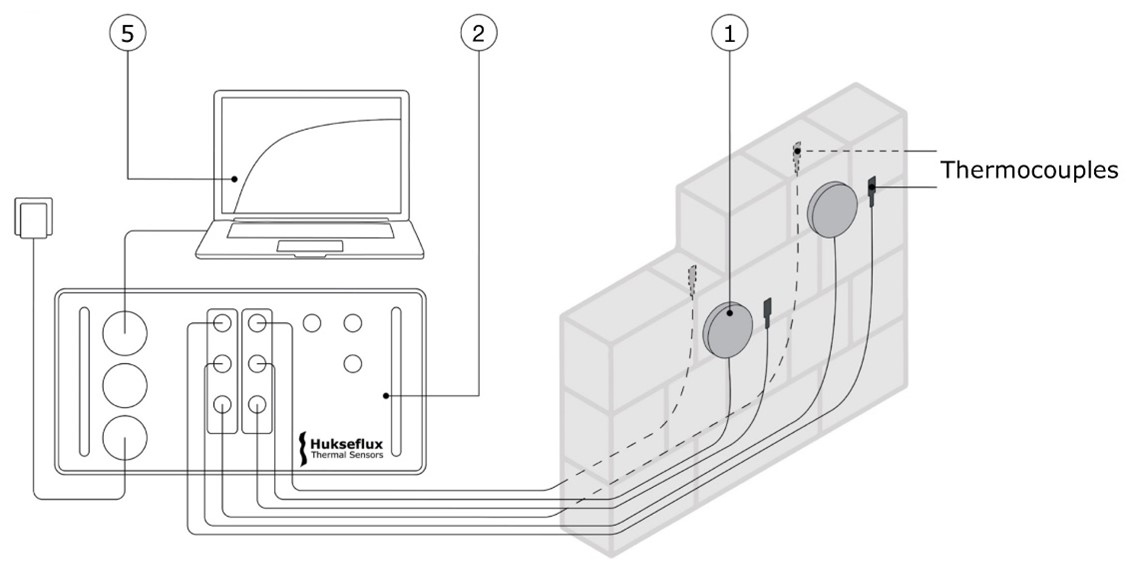

The TRSYS20 thermal resistance measuring system is a system that is used to measure the heat transfer through a wall. This is important if you want to know the insulating capabilities of a wall.

The TRSYS20 system performs these measurements using two HPF01 heat flux sensors and four thermocouples. Figure 3 shows how these sensors are applied to the wall.

One heat flux sensor (1) is placed on the inside of the wall, and thermocouples are placed on both sides of the wall to measure the temperature difference across the wall. This is done twice to ensure that the measurement results are representative for the wall (or other building envelope components).

The Measurement and Control Unit (MCU) (2) collects data from the sensors and uses this to calculate the following values:

- Thermal resistance (R-value)

- Thermal conductance (Λ-value)

- Thermal transmittance (U-value)

The data logger (2) in the figure performs the actions of steps 2-5 in the measuring chain: it can calculate, convert, and store data,

as well as keep time (which is paramount in heat flux measurements).

The MCU can be connected to an output device via a LAN or a USB output.

The numbers seen in Figure 3 correspond with the steps of the measuring chain seen in Table 1. The data logger (2) in Figure 3 is not only a voltmeter, but also converts the voltage to heat flux (using the heat flux sensor sensitivity), keeps time and can store data for up to 30 days of measurements. These functions make the TRSYS20 a versatile heat flux measurement system.

For a more detailed explanation of how the TRSYS20 is used, read the article: Heat transfer through a wall and insulation of a wall.

TCOMSYS01 Hot Cube

Hot Cube (bottom left), Measurement and

Control Unit (bottom right) and a carrying

case (middle).

The TCOMSYS01 Hot Cube, seen in Figure 4, is a system that measures heat flux to gain insight into the thermal comfort level a human being would experience. It does this by using the innovative Hot Cube method. This Hot Cube (the cube on a tripod in Figure 4) measures heat flux in five different directions using black-coated heat flux sensors, which measure both radiative and convective heat flux. Air temperature and relative humidity have a strong impact on the thermal comfort of a human being, so these are also measured using a separate sensor.

The Hot Cube has a sensor body temperature stabilised at 33 °C, comparable to that of a human being. The thermal comfort is decided by how much power it takes to keep the sensor body at this temperature. If the sensor body overheats, a person would feel heat stress. The same goes for undercooling; then, a person would feel cold stress. The Hot Cube can also be used to measure the effect of clothing on thermal comfort by simply putting the desired fabric over the sensor and then conducting the measurements.

Finalising your heat flux measurement system

Ultimately, the kind of heat flux measurement system you need depends on the application. Are you interested in conducting heat flux measurements with many sensors, or is flexibility important? Then, a data logger, in combination with heat flux sensors, will be your best option.

If you are interested in a specific application, such as thermal comfort or insulation performance, a system tailored to your needs will be ideal.

Please get in touch with Hukseflux for advice on any application you have in mind.