Which heat flux sensor to choose?

Heat flux is the transport of thermal energy through a surface area. Hukseflux specializes in measuring heat flux. One of our goals at Hukseflux is to help you select the right sensors for your thermal energy measurement.

In this article, we explain how heat flux sensors based on thermopiles are used to measure heat flux. Then, some examples of such thermal energy measurements are discussed. Next, criteria are given to help choose the best heat flux sensor. Finally, the criteria will be applied to the earlier examples to select the correct sensor for the job.

How does a heat flux sensor work?

Most heat flux sensors, including those we develop at Hukseflux, are based on thermopiles. A thermopile consists of multiple thermocouples connected to each other. Each thermocouple consists of two different electrically conducting metals or alloys. These materials have a unique reaction to temperature differences over the length of the wire. When these two materials are in contact with each other and the temperature difference changes, a voltage is generated. Sensors are calibrated so that there is a known relationship between the heat flux and the voltage output. This is expressed by the sensitivity of the heat flux sensor. A data logger can be used to measure the voltage and to convert the voltage to other units of measurement, like W/m2. In other words, by following this, you perform a heat flux measurement.

A more in-depth description of thermopiles can be found in the article: How to measure heat flux?

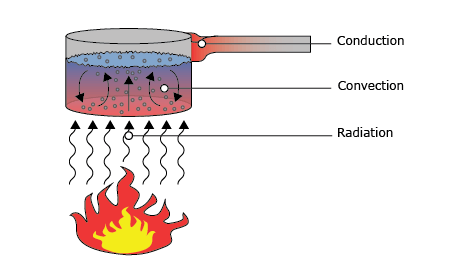

of heat flux; conduction, convection and radiation.

An introduction to heat flux measurement

Our customers at Hukseflux have many different needs when it comes to heat flux measurement. Some heat flux sensors are used in industrial environments where operating conditions are harsh and sensor range is more important than sensitivity. Others are used on walls of buildings, where the heat flux range is small, but sensitivity is very important.

Three types of heat transfer

Then there are also the different types of heat transfers: conduction, convection and radiation. Here is a short overview of how these three differ from each other, see overview below. These three types of heat transfer make up the total heat flux. For more information about heat flux read the article: How to measure heat: temperature versus heat flux.

We will give some criteria based on four examples that can help you find the best heat flux sensor for your application in the next paragraph.

| Conduction: Heat is transferred through solid material, or a connection of two solids. |

| Convection: Heat is transferred through liquids or gases. |

| Radiation: Heat is transferred through electromagnetic waves, there is no medium needed, so it can also take place in a vacuum. |

Heat flux measurements for boiling water taps

its flexibility makes it perfect to measure the heat flux

on non-flat surfaces.

Boiling water taps work by using a small tank underneath the tap that contains water at 108 °C, giving instant access to boiling water. It is important that the tank has an airtight seal to make it as efficient as possible. During the production of such tanks, the level of insulation should be verified.

The FHF05 heat flux sensor is used to see how much heat is lost to the environment when the tank is heated from the inside. If the heat flux is within a set range, the manufacturer knows that the tank has the right thermal insulation.

To measure the heat flux on the round tank used for the boiling water tap, a flexible sensor was needed. The testing temperature for the tank lies around 108 °C, and the estimated heat flux around 10 W/m2. This made the FHF05 the right sensor for this measurement. You can see how the FHF05 sensor can be applied to a round surface in Figure 2.

Heat flux sensors in Concentrated Solar Power (CSP)

squares are mirror configurations called heliostats. These heliostats

are individually controlled to focus the sunlight onto the central tower.

Photo: Unsplash.

Concentrated Solar Power (CSP) is a way to generate energy by focusing mirrors, called heliostats, onto a central tower. A fluid, often molten salt, that flows through this tower heats up and can be used to generate energy inside a turbine. The molten fluid is also oftenly used to store energy by keeping it inside tanks, making the CSP plant ideal to deliver a reliable constant power supply instead.

Hukseflux has partnered with an American research facility to work on improving the sensors that are currently used with concentrated solar power. The heat flux reaches a value of 1 000 000 W/m2 and higher. These heat flux conditions would melt a plastic heat flux sensor such as the FHF05, but a water-cooled Gardon gauge would be able to withstand these conditions and perform measurements for longer periods of time.

Gardon gauges are water-cooled heat flux sensors, specially designed to measure high radiative heat fluxes. The water cooling makes them more capable of measuring high heat fluxes than other non-water-cooled sensors. An option for our Gardon gauge is the addition of a sapphire window. The gauge then only measures the radiative heat flux and is no longer sensitive to convective heat flux.

So far we have seen that the range of the heat flux has an influence on what type of heat flux sensor one should choose for their application and also that the operating temperature is an important criterion. One thing we have not yet seen is how environmental factors, other than temperature, impact our sensor choice.

Which heat flux sensors can I use in extreme environments?

One of these factors is water and dust protection which is rated using the IP scale. IP (Ingress Protection) stands for the amount of protection the sensor has against water, dust and other small particles. IP68 is the highest rating providing protection from water under pressure for long time periods. IP66 and 67 are more commonly associated with our heat flux sensors, providing protection against powerful water jets and light submersion, respectively.

A more extreme factor to take into account is explosive environments, these are more closely observed by law than wet environments.

Naturally, working in possibly explosive environments can be dangerous. Legislations such as the ATEX (Atmosphères Explosibles) provide requirements for equipment and safety systems that are used on (but not limited to) offshore platforms, mines, blast furnaces and flour mills.

damaging the sensor. The metal-sheathed signal cable is also weather-proof.

One of our heat flux sensors that complies with ATEX standards is the IHF01. This sensor can be used for many industrial applications like furnaces and ovens both indoors and outdoors due to its stainless steel body and high-temperature cable. These industrial applications must often follow specific laws to ensure operator safety.

The HF02 is another example of how heat flux measurements are applied to ensure safety in these explosive environments. This sensor is also called a flare radiation monitor. It is made for use outdoors and works by pointing it at the radiation source of interest. It is not made to measure the exact radiation, but to act as a decision supporting device. The HF02 measurements are influenced by weather conditions like rain, as can be seen in Figure 4. This gives an accurate representation of when an environment could be dangerous to humans.

Thermal energy measurements for heat batteries

Thermeleon, a Dutch start-up, has been developing a way for greenhouses to decrease their energy consumption by 30%. This is done by using heat batteries. These heat batteries store excess thermal energy during the day and release it during the night. This saves energy while increasing crop yields by supplying them with more optimal growing conditions.

In their research, Thermeleon needed to measure the intake of thermal energy of the thermal mass used in the heat battery. They were also interested in the convective heat flux to find out if all crops experience the same temperature conditions at certain heights.

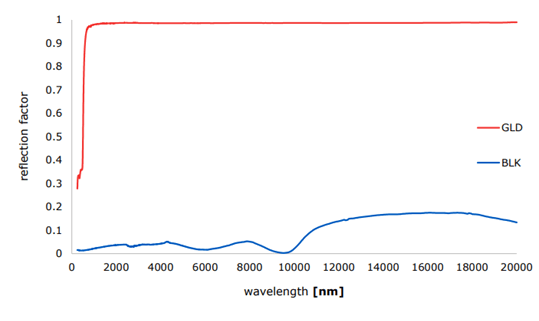

Inside the greenhouse, both radiative and convective heat flux measurements were needed. These two types of heat flux can be measured separately by applying our black (BLK) and gold (GLD) stickers to the heat flux sensor, this can be done on your own or during our production process. The FHF05 was used to measure these two types of heat flux by sticking them on the glass of the greenhouse and applying these stickers.

To measure only convective heat flux, apply the GLD sticker to the sensor. By reflecting nearly 100% of the radiation, this gold sticker makes sure that only the convective heat flux influences your measurements.

Radiation (radiative heat flux) is measured by using both the BLK and the GLD stickers. The BLK sticker absorbs all radiation and is also sensitive to convective heat flux. We will get the net radiation by subtracting the heat flux of the sensor using the GLD sticker from that of the sensor using the BLK sticker.

Criteria for choosing your heat flux sensor

Now that you have a general idea of how different heat flux sensors are used in different applications, we can give a good overview of the criteria that have been mentioned.

Each criterion will be followed by applicable measurement ranges and some sensors that could be used in each case. Please note that this list is incomplete and that you can always contact us for any assistance you may need.

| Application | Applicable sensor(s) | Heat flux range (W/m2) | Temperature range(1) | Special properties |

| General | FHF05 | (-10 to +10) x 103 | -70 to +120 °C | IP67, sticker(2), thermocouple type T(3), flexible, SC(4) |

| FHF06 | (-20 to +20) x 103 | -70 to +250 °C | ||

| HFP01 | (-2000 to +2000) | -30 to +70 °C | IP67, sticker, SC | |

| HFP03 | IP67, sticker, ultra sensitive | |||

Fire & flame

| HFS01 | (0 to 800) x 103 | -30 to +650 °C | IP67, water-cooled, thermocouple type k |

| SBG01 | (5,10,20,50,100,200) x 103 | -30 to +80 °C | IP10, thermocouple, water cooled | |

| SBG04 | (10 to 100) x 103 | Water-cooled, often used in cone calorimetry | ||

| High heat flux | GG01 | (250, 500, 1000) x103 | -30 to +800 °C | Thermocouple, water-cooled |

| HFS01 | (0 to 800) x 103 | -30 to +650 °C | IP67, water-cooled, thermocouple type k | |

| IHF01 | (-1000 to +1000) x 103 | -30 to +900 °C | IP67, thermocouple type k. ATEX certified | |

| IHF02 | (-100 to +100) x 103 | IP67, thermocouple type k, ultra sensitive, ATEX certified | ||

| SBG01 | (5,10,20,50,100,200) x 103 | -30 to +80 °C | IP10 water-cooled | |

| Industrial | IHF01 | (-1000 to +1000) x 103 | -30 to +900 °C | IP67, thermocouple type k, ATEX certified |

| IHF02 | (-100 to +100) x 103 | IP67, thermocouple type k, ultra-sensitive, ATEX certified | ||

| HF02 | (0 to 15) x 103 | -50 to +300(5) °C | IP68, thermocouple type KX, used in alarm systems | |

| HF05 | (-6000 to +6000) x 10 | -30 to +170 °C | IP67, thermocouple type k |

1 Continuous use, see website for short interval temperature ratings (if applicable).

2 BLK and GLD sticker available

3 Integrated thermocouple

4 Self-calibrating version is also available

5 Operating temperature, measuring range is -30 to +100 °C

Many more criteria exist to take into account when choosing the correct heat flux sensor like size, spectral properties, response time and sensitivity. Contact Hukseflux for assistance and a personalized recommendation for your specific needs.