Environmental impact of SR30 compared with externally ventilated pyranometer

SR30 environmental impact analysis, comparison with externally ventilated conventional pyranometers

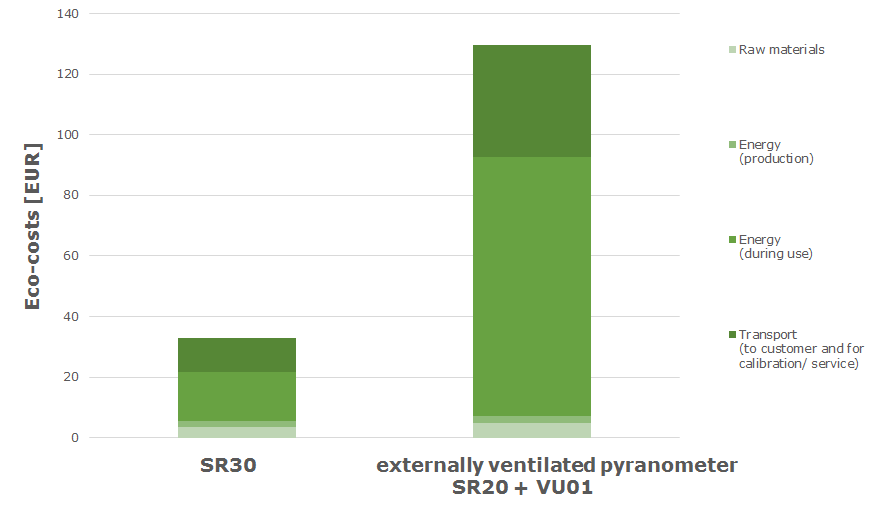

We analysed the environmental impact of SR30 pyranometer by comparison with its nearest competitor, an externally ventilated and heated pyranometer, also classified as ISO 9060 Class A. We took model SR20 with ventilation unit VU01 to compare with SR30. The outcome: SR30’s environmental impact is three times lower due to lower energy consumption and smaller transport volume!

Read the full article here: Environmental impact of SR30 compared with externally ventilated conventional pyranometers - note (PDF)

Introduction

In general, customers show an increasing concern in the environmental impact of the products they use; so do users of pyranometers. Here is an example of our analysis of the impact of Hukseflux SR30 pyranometer. Figure 1 shows the impact comparison between SR30 Class A pyranometer and SR20 Class A pyranometer with external ventilation (VU01). The SR30 environmental impact is three times lower compared to the SR20 with a VU01.

For analysis, we used “Eco-costs”; Box 1 and the following paragraphs explain the analysis.

| ECO-COSTS (BOX 1) |

|---|

For analysis we use “Eco-costs”; a measure to express the amount of environmental burden of a product on the basis of prevention of that burden. They are the costs which should be made to compensate for the environmental pollution and materials depletion in our world to a level which is in line with the carrying capacity of our earth.For example: for each 1000 kg CO2 emission, one should invest EUR 116 in offshore windmill parks (and the other CO2 reduction systems at that price or less). In short: "the eco-costs of 1000 kg CO2 are EUR 116" (text reference ecocostsvalue website DEC 2019).Want to know more? > http://www.ecocostsvalue.comThe Eco-costs website offers free of charge datasets. Analysis is based on the datasets available in NOV 2019. |

Figure 1 Eco-costs comparison over a 10-year lifetime between SR30 and its nearest alternative: SR20 with VU01 ventilation unit.

Analysis

We studied the environmental impact of our model SR30 heated spectrally flat Class A pyranometer and compared it with the nearest competitor, an externally ventilated pyranometer, in this case model SR20. Both are offering a solution to mitigate dew and frost.

Our analysis followed the “Eco-costs” methodology. The main outcome is that for the environmental impact, the dominant factors are energy during use and transport. SR30 has a significantly lower impact due to lower power consumption during use and lower transport volumes.

Assumptions

We have used the following assumptions:

- 10-year product lifetime

- re-calibration every 2 years (4 times over its lifetime)

- ventilator servicing every 4 years

- continuous use of ventilator and heating

SR30 versus SR20 + VU01

The differences between SR30 and the SR20+ VU01 combination are in power consumption during use, and transport volume:

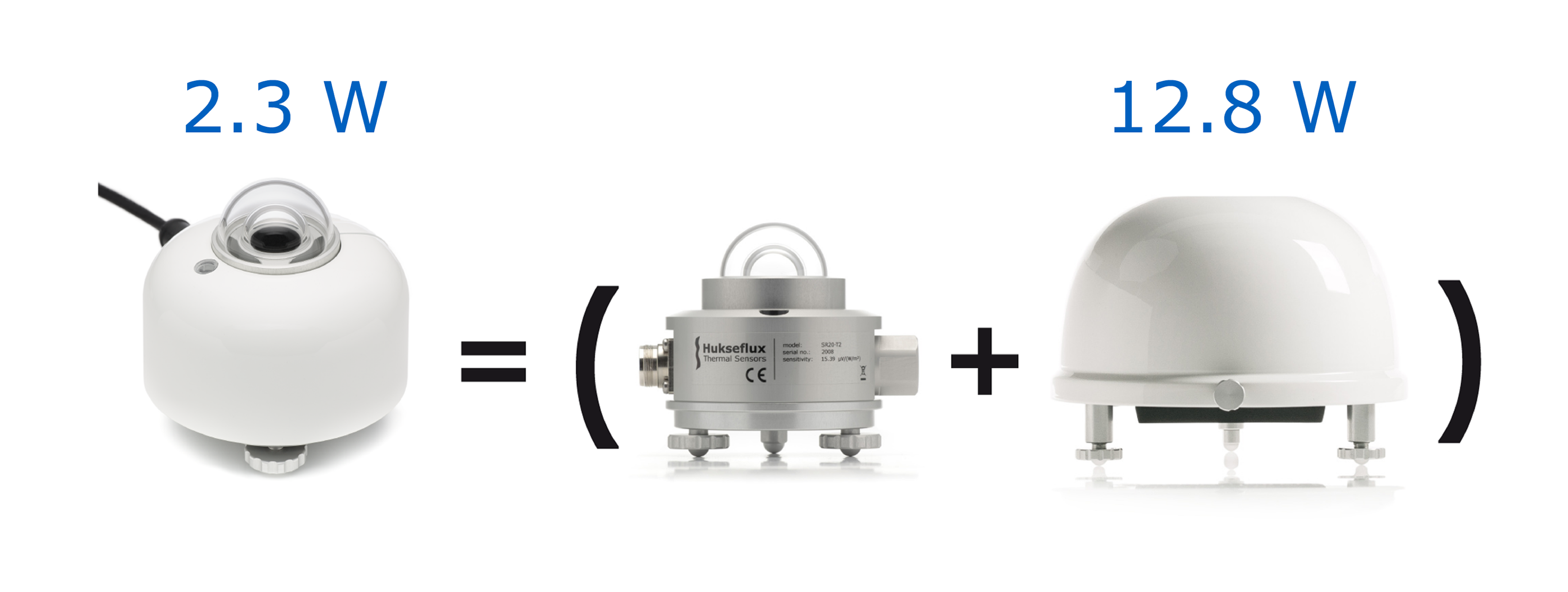

- 2.3 W versus 12.8 W

- 1 transport box versus 2 transport boxes

Figure 2 SR30 digital spectrally flat Class A pyranometer with internal ventilation, heating and tilt sensor is compared with an SR20 analogue spectrally flat Class A pyranometer equipped with a VU01 external ventilation unit.

New: SR30-D1 with internal recirculating ventilation and heating

A new solution to mitigate dew and frost is internal recirculating ventilation. Internally heated and recirculated air keeps the instrument dome, above the dew point and at the same time it forces the body to the same temperature. See also Figure 6.

Internal ventilation:

- heats air and blows internally through the instrument so that the dome is above dew point

- makes sure the entire pyranometer is in thermal equilibrium, reducing zero offsets

- does not require extra heaters

- has no additional zero-offsets at high heating

- consumes low power because the heat is recirculated; 2 W consumption is normal

- requires replacement of the ventilator after > 5 year

...

Read the full article here: