Industrial monitoring and control / heat flux and heat transfer measurement

Hukseflux' heat flux sensors can be used in industrial measurement and control systems. Examples of applications are analysis of aluminium reduction cells, detection fouling in boilers (Boiler Slagging / Fouling Sensor), monitoring of blast furnaces (Blast Furnace Safety System / General Furnace Monitoring), flame monitoring and composites processing.

Heat flux and heat transfer measurement

Many industrial systems rely on temperature measurements. Heat flux and heat transfer measurements offer additional information. A change of temperature usually goes together with a heat flux. Measuring both quantities offers a better picture of what is happening. Heat flux can often be detected earlier than a temperature change. This offers advantages, for example better process control and faster response to emergency situations.

The measurements are used for several purposes:

- Process monitoring: Creating a performance baseline

- System protection: detection of failures in cooling systems

- System energy efficiency: detection of wear of insulating layers

- Process monitoring: detection of deposition of fouling

- Personnel safety: measurement of heat stress by radiation

- Energy efficiency: studies of insulation / thermal resistance

What is measured

Heat flux sensors measure heat transfer. More specifically: the energy flux onto or through a surface, in [W/m²]. In reality this surface is the sensor itself. The source of the heat flux may be:

- conduction - heat flowing through a static, not-flowing material

- radiation - heat transmitted, typically by visible or infra-red, radiation

- convection - heat transported by flowing fluids or gasses

Heat transfer is driven by temperature differences. Heat always flows from a source to a sink, from a hot to a cold environment.

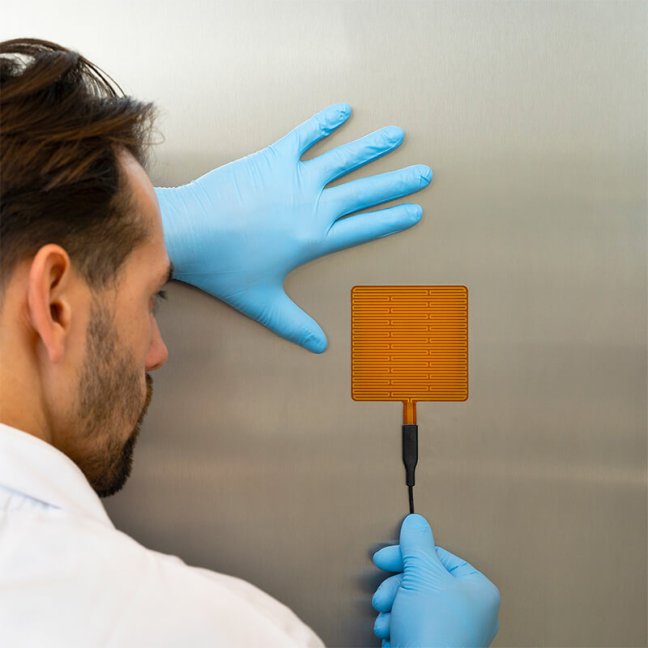

Convective and conductive heat fluxes are measured by letting this heat flow through a heat flux sensor. Heat flux sensors are either mounted on a surface of a solid object or embedded into this object. Measuring convective heat flux, the sensor will typically be located on the surface of a solid object, and exposed to the convective flow; at the sensor surface, the convective flux is then converted into a conductive flux.

Radiative flux is measured using a heat flux sensor covered with a (black) radiation absorber. It is usually mounted on a solid, well conducting heat sink. The absorber converts radiative energy to conductive energy.

At the surface of a solid object, often the source of heat flux is a mixture of radiative and contributions.

Heat flux measurement is typically combined with temperature measurement. Relative to conventional monitoring based on temperature, use of heat flux sensors improves insight in processes and often leads to faster response times for process control and emergency response.

Specifications

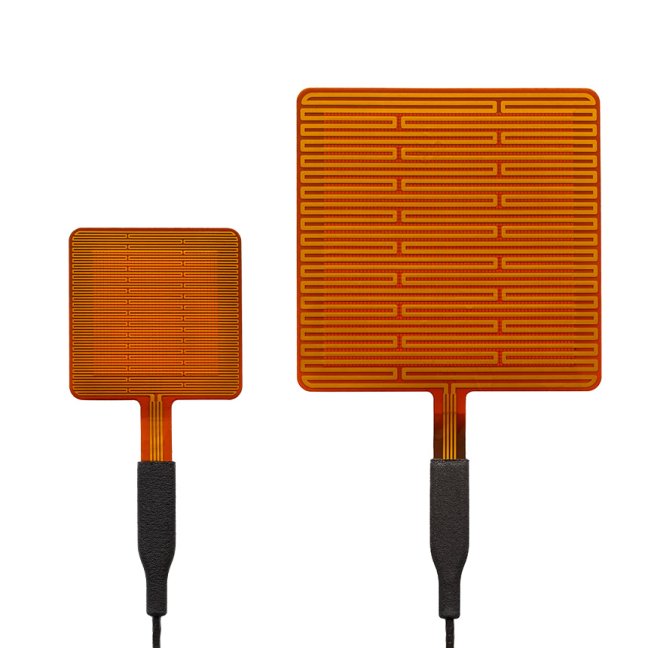

Some heat flux sensor models, we call these “self-calibrating”, have integrated heaters, so that the user may perform on-site performance checks. This is useful if sensors cannot be removed, or can only be removed at high cost.

Heat flux sensors manufactured by Hukseflux are optimised for the demands of different applications:

- rated temperature range; we make sensor for use from -150 to + 900 °C

- rated heat flux range; from 0.01 to 200 000 W/m²

- sensitivity / output signal

- response time

- chemical resistance, safety requirements; including sensors for potentially explosive environments

- size, shape and spectral properties

- optional on-site performance validation or self-calibration capabilities

Products are manufactured under ISO 9001 quality management system. If applicable, the sensors comply with industrial standards such as ITS90, ANSI, DIN, and BS. Sensors for hazardous areas can be manufactured according to safety standards like EExi, ATEX / Cenelec and NAMUR.

Selecting a sensor

We can assist you selecting a sensor. For preparation, please read:

- our note about general things to keep in mind when measuring heat flux, also showing different sensor models and their most common applications

also note:

- some measurements are standardized like those for building thermal resistance, flammability testing; you have no choice what procedure to follow

- with many applications you will find a dedicated model

a typical checklist is:

- what is the application, what must be measured

- are there any standard that you must follow

- any requirements for size and shape

- what are the accuracy requirements

- how do I organise re-calibration; do we need on-site performance validation or self-calibration capabilities

- how can I mount the sensor

- what is the rated temperature range in °C

- what is the rated heat flux range in W/m²

- what data acquisition do I have, can it measure in the millivolt range; if not what kind of input can it accept?

- what other things must be measured; usually it is best to use one measurement system performing all measurements

- any special requirements for example response time, spectral properties, ..

- any special environmental conditions, requiring chemical resistance, protection against water or dust, approvals for Ex safety, approvals for potentially explosive environments

- what is the required cable length

What we contribute

Hukseflux company started in 1993 making sensors for measurement of heat flux in soils and on walls. In the course of the years, we have added many “special purpose” sensors and systems for other applications. We have designed and supplied sensors for many industrial projects. Our experience includes a variety of environments such as coal fired boilers, fluidised beds, solar concentrators, offshore flare systems and blast furnaces. We are the market leader in industrial heat flux and heat transfer measurement.

Advantages

Hukseflux is the world market leader in heat flux measurement. We offer:

- assistance - select the best sensor for your application

- assistance - optimising the sensor – measuring system combination, also looking at the total system (our users often measure more than just heat flux)

- worldwide support – specialists available in the major economies

- proven performance - in most applications we have experience

- proper certification - CE, ATEX, ASME approvals

- traceability - formal metrological traceability to international standards.

Take a look at our selection of suitable sensors: