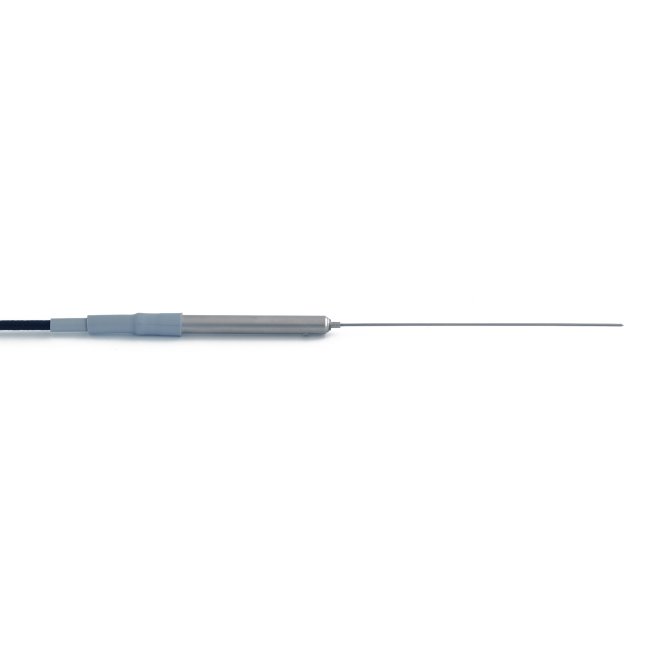

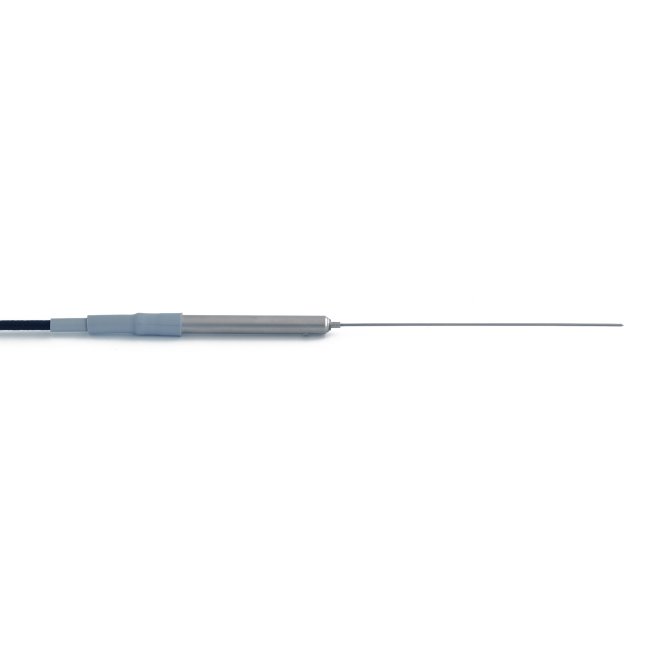

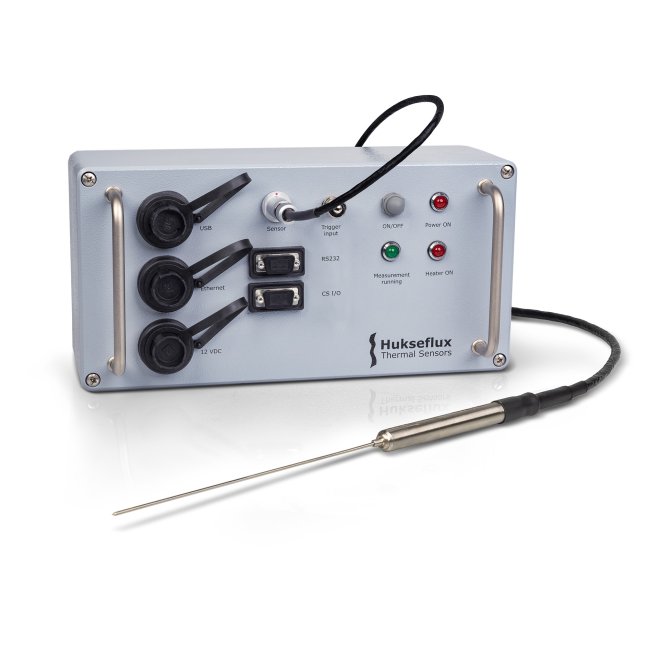

Non-steady-state probe for thermal conductivity measurement

TP02 is a probe that offers the possibility to perform a practical and fast measurement of the thermal conductivity (or thermal resistivity) of the medium in which it is inserted at the highest accuracy level. It works in compliance with the ASTM D5334-14, D5930-97 and IEEE 442-1981 standards. The standard TP02 probe has proven suitability in soils, thermal backfill materials, sediments, foodstuff, powders, sludges, paints, glues and various other materials. The Non-Steady-State Probe (NSSP) measurement method (also known as transient line source, thermal needle, hot needle, heat pulse- and hot wire technique) has the fundamental advantages that it is fast and absolute while the sample size is not critical. Hukseflux is specialised in NSSP design. Special models have been developed for in-situ field experiments. For permanent installation in soils, a dedicated model, TP01, is available. TP02 has been designed and tested in collaboration with the Applied Physics Group of Wageningen University.

or contact us: info@hukseflux.com